Medical needles are used for a variety of medical procedures, including injections, blood draws, and IV access. They come in different sizes and types and are made using a specific production process. In this article, we will discuss the species, types, production process, distribution of industry chain, manufacture plant quantity, and capacity of medical needles.

Species

Medical needles can be classified into two species: hypodermic needles and phlebotomy needles. Hypodermic needles are used for injections and come in different gauges and lengths. Phlebotomy needles are used for drawing blood and are typically longer and have a larger gauge than hypodermic needles.

Types

Medical needles come in various types, including straight needles, curved needles, safety needles, and winged needles. Straight needles are the most common type of needle and are used for injections and IV access. Curved needles are used for suturing wounds and can have a variety of shapes, such as straight, curved, and half-curved. Safety needles have features that reduce the risk of needlestick injuries, such as a retractable needle. Winged needles, also known as butterfly needles, are used for drawing blood and are designed with a small wing on either side of the needle for stability.

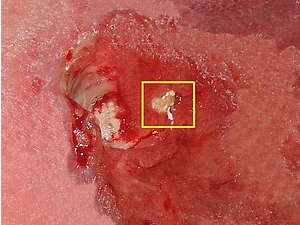

Production Process

The production process of medical needles involves several steps, including the manufacturing of the needle tube, point grinding, and surface treatment. The needle tube is made using a process called cannula manufacturing, where a thin metal tube is drawn through a series of dies to form the shape of the needle. The point grinding process sharpens the end of the needle to ensure smooth and precise insertion. The surface treatment process involves cleaning and coating the needle to improve its biocompatibility and reduce friction during insertion.

Once the needle is manufactured, it is packaged and sterilized using ethylene oxide gas or gamma irradiation.

Distribution of Industry Chain

The medical needle industry chain is composed of several stages, including raw material production, component manufacturing, needle assembly, and distribution. Raw materials, such as stainless steel and plastic, are produced by suppliers and sold to component manufacturers. Component manufacturers produce the needle tube and other components and sell them to needle assembly plants. Needle assembly plants assemble the components into the final product and distribute them to hospitals, clinics, and other healthcare providers.

Manufacture Plant Quantity and Capacity

The manufacture plant quantity and capacity of medical needles vary depending on the company and location. Many of the largest medical needle manufacturers are based in Asia, particularly in China and India. According to a recent report by Grand View Research, the global medical needle market was valued at $5.3 billion in 2020, with Asia-Pacific accounting for the largest share of the market. The report also projects that the market will continue to grow in the coming years, driven by increasing demand for vaccinations and the growing prevalence of chronic diseases.

In conclusion, medical needles are an essential tool in healthcare, used for a variety of medical procedures. They come in different sizes and types and are made using a specific production process. The medical needle industry chain is composed of several stages, including raw material production, component manufacturing, needle assembly, and distribution. The manufacture plant quantity and capacity of medical needles vary depending on the company and location, with many of the largest manufacturers based in Asia.